- Deal includes firm order for 40 GEnx engines, 20 GE9X engines, plus services

- Largest LEAP* engine order ever with more than 800 LEAP engines chosen for entire firm order of 400 Airbus and Boeing single-aisle aircraft

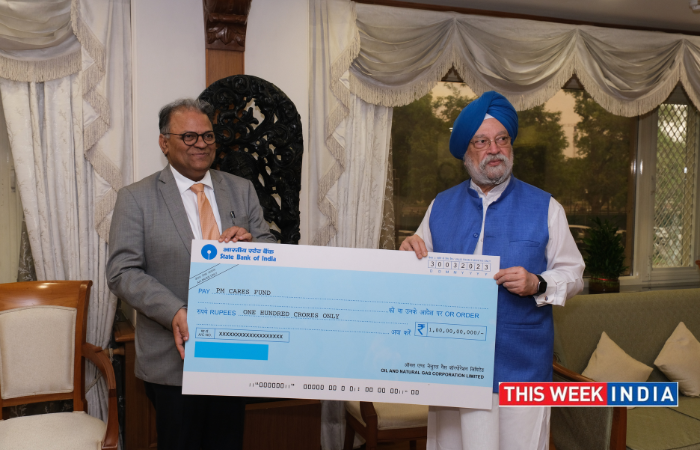

FEBRUARY 15, 2023 Bangalore, INDIA – Air India, part of Tata Sons, has signed a firm order for 40 GEnx-1B and 20 GE9X engines, plus a multi-year TrueChoice™ engine services agreement. The deal was signed in coordination with the airline’s firm order for 20 Boeing 787 and 10 Boeing 777X aircraft.

“All of us at Tata Group and Air India are delighted to have this partnership with GE Aerospace, where we will build Air India to be a world class airline and one of the most technology-advanced airlines,” said Mr. N. Chandrasekaran, Chairman of Tata Sons and Air India.

“We are proud to continue our longstanding partnership with Tata Group and Air India,” said H. Lawrence Culp, Jr., Chairman and Chief Executive Officer of GE and CEO of GE Aerospace. “We look forward to working together to introduce these engines into Air India’s fleet and are committed to ensuring they deliver exceptional performance.”

GE Aerospace has powered Air India since 1982, when the airline took delivery of its first CF6-powered Airbus A300. The airline currently operates a fleet of more than 150 aircraft, including GE90-powered Boeing 777s and GEnx-powered Boeing 787s.

Air India also announced a CFM order for more than 800 LEAP engines, the largest LEAP order ever, to power its entire narrowbody purchase of 210 Airbus A320/A321neo aircraft and 190 Boeing 737 MAX-family aircraft. The announcement includes a multi-year CFM services agreement. CFM is a 50/50 joint business between GE and Safran Aircraft Engines.

“This order for GE Aerospace engines supports our Vihaan.AI transformation plan, a key part of which is to dramatically expand our fleet and global network,” said Campbell Wilson, CEO & Managing Director of Air India. “We are confident that these engines will deliver the reliability and efficiency we need, and we are delighted to continue our longstanding relationship with GE.”

“Over the last decade, we have introduced a new portfolio of commercial engines that are significantly more fuel efficient, quieter, and emit less CO2,” said Russell Stokes, President and CEO, Commercial Engines and Services for GE Aerospace. “This record order reflects our strong product renewal and our customer’s continued confidence in our engines.”

Today’s announcement includes GE and CFM’s most technically advanced commercial engines:

- The GE9X, the world’s most powerful and GE’s most fuel-efficient turbofan, powers the Boeing 777X family of aircraft. The engine offers the lowest NOx emissions in its class, 55% below current regulatory requirements. It is also the quietest GE engine ever produced on a pounds of thrust per decibel basis.

- The GEnx, powers the Boeing 787-8 Dreamliner, has an innovative lean burning twin-annular pre-swirl (TAPS) combustor that dramatically reduces NOx and other regulated gases below today’s regulatory limits, offering 15% better fuel burn than the CF6 engine.

- The LEAP-1A and LEAP-1B, have accumulated more than 27 million flying hours. LEAP operators are reporting up to a 20 percent improvement in fuel efficiency and CO2 emissions compared to the latest production CFM56 engines, resulting in an average of more than 17 million tons of CO2 emissions reduction.

Like all GE and CFM engines, the GEnx, GE9X and LEAP are compatible with all approved Sustainable Aviation Fuel (SAF) blends.

GE Aerospace also provides multiple systems for the Boeing 777X. This includes the Enhanced Airborne Flight Recorder (EAFR), the Electrical Load Management System (ELMS) and the Backup Generator, Backup Converter (BUG/BUC) and the Common Core System (CCS). The CCS is often referred to as the “central nervous system and brain” of the airplane and hosts the aircraft’s avionics and utilities functions, eliminating several boxes and reducing hundreds of pounds of wire. GE Aerospace also supplies the CCS and EAFR for the Boeing 787.

GE Aerospace has been operating in India for over four decades with wide engagement in the industry including engines, avionics, services, engineering, manufacturing, and local sourcing.

Engineers at the John F. Welch Technology Centre (JFWTC) in Bangalore, India, GE’s research and development center, have played a key role in the technology development of the GE9X, GEnx, and CFM LEAP engines by providing analysis and test validation support. The center has close to 1,000 engineers working to support next-gen technologies to reduce CO2 emissions.

*LEAP is a trademark of CFM International, a 50/50 joint company between Safran Aircraft Engines and GE